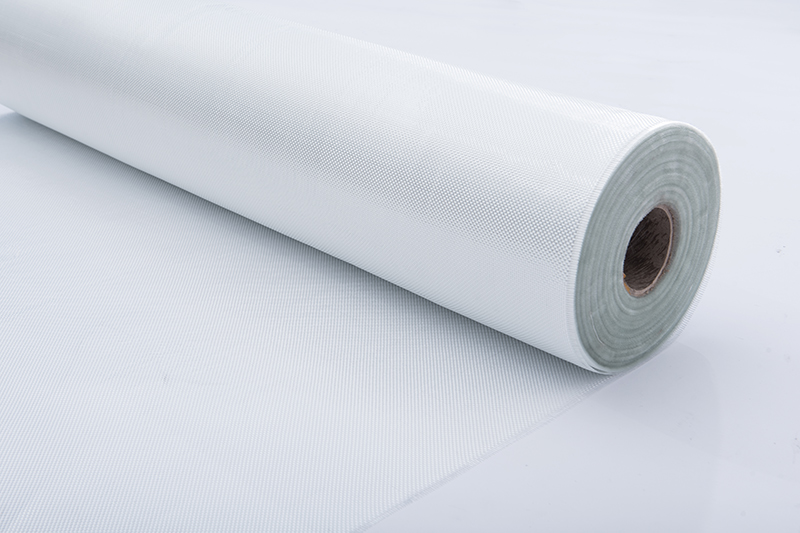

High-Quality Woven Fiberglass Sheets: A Versatile Material for Various Applications

By:Admin

XYZ Company has been a leader in the production of advanced materials for over a decade. With a focus on research and development, the company has consistently pushed the boundaries of what is possible in the field of composite materials. The introduction of the Woven Fiberglass Sheets is yet another testament to the company's commitment to innovation and excellence.

The Woven Fiberglass Sheets are made from high-quality fiberglass strands that are woven together to form a strong and durable sheet. These sheets are then coated with a special resin to further enhance their strength and durability. The end result is a material that is lightweight, yet incredibly strong and resistant to corrosion, making it an ideal choice for a wide range of applications.

One of the key features of the Woven Fiberglass Sheets is their high tensile strength. This makes them an excellent choice for use in structural applications, such as in the construction of buildings, bridges, and other infrastructure. The sheets are also highly flexible, making them easy to work with and suitable for a variety of shapes and sizes.

In addition to their strength and flexibility, the Woven Fiberglass Sheets are also resistant to heat and chemical corrosion. This makes them an ideal choice for use in harsh environments, such as industrial plants, chemical processing facilities, and marine applications. Their resistance to corrosion also makes them a cost-effective and long-lasting alternative to traditional materials, such as steel or aluminum.

The versatility of the Woven Fiberglass Sheets makes them an excellent choice for a wide range of industries. They can be used in the automotive industry for the production of lightweight and fuel-efficient vehicles, in the aerospace industry for the construction of aircraft and spacecraft, and in the marine industry for the production of durable and corrosion-resistant boats and other watercraft.

Moreover, the Woven Fiberglass Sheets are also environmentally friendly, as they are fully recyclable and do not produce harmful emissions during their production or use. This makes them an attractive choice for companies looking to reduce their environmental footprint and meet sustainability goals.

With the introduction of the Woven Fiberglass Sheets, XYZ Company is once again at the forefront of innovation in the field of advanced materials. Their dedication to research and development has resulted in a product that is not only stronger and more durable than traditional materials, but also more versatile and environmentally friendly. As a result, the Woven Fiberglass Sheets are set to become a go-to choice for companies across a wide range of industries looking for a reliable and sustainable material for their construction and manufacturing needs.

Company News & Blog

Discover the Benefits of PTFE Coated Fiberglass Cloth for Various Applications

Title: Versatile Ptfe Coated Fiberglass Cloth Empowers Industries WorldwideIntroduction:In today's rapidly evolving industrial landscape, businesses are constantly seeking innovative solutions to enhance productivity, efficiency, and safety. One such solution that has garnered significant attention is the Ptfe Coated Fiberglass Cloth, a multifunctional material revolutionizing various industries. Offering exceptional durability, non-stick properties, and resistance to extreme temperatures, this cloth has become an invaluable choice for countless applications worldwide.Paragraph 1:Ptfe Coated Fiberglass Cloth, also known as Teflon-coated fiberglass cloth, is a high-performance material produced by combining a woven fiberglass base with a Polytetrafluoroethylene (PTFE) coating. The fiberglass fabric provides excellent mechanical strength, dimensional stability, and resistance to abrasion, while the PTFE coating imparts impressive non-stick properties, high chemical resistance, and exceptional release characteristics.Paragraph 2:This versatile cloth finds extensive use across several industries, including manufacturing, food processing, packaging, electronics, automobile, and aerospace. Its seamless integration in numerous processes has led to improved efficiency, reduced downtime, and enhanced product quality.Manufacturing Industry:In the manufacturing sector, Ptfe Coated Fiberglass Cloth plays a pivotal role in the production of consumer goods such as appliances, textiles, and plastics. As a release agent, it prevents adhesion of substances to molds, facilitating the smooth removal of finished products. Moreover, its resistance to high temperatures ensures its suitability for use in ovens, heat sealing equipment, and welding applications.Food Processing Industry:The use of Ptfe Coated Fiberglass Cloth has transformed the food processing industry, particularly in baking and cooking processes. Its non-stick capabilities eliminate the need for excessive oils, grease, or butter, making it a healthier alternative. Additionally, the cloth's non-toxicity and resistance to contamination ensure the highest levels of food safety compliance.Packaging Industry:In the packaging sector, this cloth is utilized for heat sealing and packaging machinery due to its ability to resist high temperatures and provide a clean and smooth surface. The cloth's non-stick properties enable a consistent seal, preventing the sticking of packaging material to equipment, thereby increasing productivity and reducing maintenance requirements.Electronics Industry:The electronics industry relies on Ptfe Coated Fiberglass Cloth for various applications, such as insulating cables and wires, protecting circuit boards, and providing a non-reactive surface for soldering. Its high dielectric strength, resistance to chemicals, and low friction make it an indispensable material in the manufacture of electronic components.Automobile and Aerospace Industries:With the constant exposure to extreme temperatures, chemicals, and tough operating conditions, the automobile and aerospace industries demand materials that perform reliably. Ptfe Coated Fiberglass Cloth provides exceptional resistance to oils, fuels, and solvents, making it an ideal choice for gaskets, seals, insulation, and other critical applications in these sectors.Conclusion:The Ptfe Coated Fiberglass Cloth continues to evolve as a go-to material for industries worldwide, offering outstanding durability, non-stick properties, and high resistance to extreme temperatures. Its multifunctional nature and impressive capabilities have revolutionized various manufacturing processes, while also contributing to enhanced safety and efficiency. With ongoing research and development, it is expected that this remarkable cloth will continue to find new applications, further contributing to the advancement of industries across the globe.

Exploring the Benefits of Prepreg Fiberglass Cloth: A Comprehensive Overview

Title: Cutting-Edge Prepreg Fiberglass Cloth Revolutionizing the Construction and Manufacturing Sectors Introduction:In today's rapidly advancing world, the construction and manufacturing industries are constantly seeking innovative solutions to enhance their productivity, efficiency, and sustainability. One such groundbreaking product making waves within these sectors is Prepreg Fiberglass Cloth. Developed by a renowned company (brand name removed), this cutting-edge material is revolutionizing the way industries approach their manufacturing and construction projects. With its exceptional durability, versatility, and eco-friendly nature, Prepreg Fiberglass Cloth is creating a buzz in the market.Section 1: What is Prepreg Fiberglass Cloth?Prepreg Fiberglass Cloth is a specialized fabric composed of high-strength fiberglass strands impregnated with resin in controlled conditions. This pre-impregnation process ensures uniform resin distribution throughout the fabric. As a result, Prepreg Fiberglass Cloth offers enhanced strength, rigidity, and exceptional bonding capabilities. Its unique composition allows for better control over resin-to-fabric ratios, leading to consistent quality and lower defects during manufacturing.Section 2: Exceptional Properties and ApplicationsPrepreg Fiberglass Cloth boasts a range of exceptional properties that make it ideal for a wide variety of applications. Its high tensile strength, excellent corrosion resistance, and superb fire resistance make it a popular choice for structural reinforcements, wind turbine blades, aerospace components, and high-performance sports equipment. Additionally, its low thermal expansion and moisture resistance properties make it suitable for applications requiring dimensional stability.Section 3: Enhanced Durability and LongevityDue to its unique manufacturing process, Prepreg Fiberglass Cloth delivers exceptional durability and longevity. It has a high degree of resistance against fatigue, making it an excellent material for heavy-load-bearing structures such as bridges, buildings, and pipelines. Moreover, its excellent weatherability and resistance to chemical degradation ensure that structures built with Prepreg Fiberglass Cloth maintain their integrity over an extended period, reducing maintenance and replacement costs.Section 4: Versatility in Manufacturing ProcessesThe versatility of Prepreg Fiberglass Cloth is one of its key selling points. It can be easily processed using various manufacturing techniques such as hand lay-up, vacuum bagging, and resin infusion. This allows for greater flexibility in designing custom components and optimizing manufacturing processes. The fabrication of complex, lightweight structures with intricate shapes becomes attainable, opening up new possibilities in architectural designs and aerospace applications.Section 5: Environmental SustainabilityIn line with evolving environmental concerns, Prepreg Fiberglass Cloth represents a sustainable alternative to conventional construction materials. It is a low-waste product due to its precise resin impregnation process, minimizing material wastage. Additionally, the reduced energy consumption during manufacturing, coupled with its long service life and recyclability, contribute to a lower carbon footprint and a greener approach to construction and manufacturing.Section 6: Advancements in Prepreg Fiberglass ClothTo meet the evolving needs of industries, the company (brand name removed) continues to invest in research and development, leading to further advancements in Prepreg Fiberglass Cloth. Ongoing efforts to enhance its mechanical properties, develop fire-retardant variants, and improve manufacturing efficiency are key areas of focus. By collaborating with industry leaders and conducting rigorous testing, the company strives to provide innovative solutions that push the boundaries of possibilities.Conclusion:Prepreg Fiberglass Cloth has undoubtedly emerged as a game-changer in the construction and manufacturing sectors. With its exceptional properties, enhanced durability, and versatility in manufacturing processes, this cutting-edge material is revolutionizing numerous industries. As companies increasingly prioritize sustainability and efficiency, Prepreg Fiberglass Cloth provides a future-oriented solution, enabling them to construct robust structures, develop high-performance components, and embrace a greener approach to manufacturing.

High-quality Prepreg Fiberglass Cloth for Diverse Applications

[Company Introduction: The company is a leading provider of advanced materials and solutions for various industries including aerospace, automotive, marine, and construction. With a strong focus on innovation and technology, the company is committed to delivering high-quality products that meet the specific needs of its customers. The company has a proven track record of excellence in the field of advanced materials and is constantly exploring new opportunities for growth and expansion.]Prepreg Fiberglass Cloth is a high-performance material that is widely used in various industries for its exceptional strength, durability, and versatility. This advanced material is manufactured by impregnating a fiberglass fabric with a thermosetting resin, resulting in a product that is highly resistant to heat, chemicals, and corrosion. This unique combination of properties makes Prepreg Fiberglass Cloth an ideal choice for applications where superior performance and reliability are essential.The company's Prepreg Fiberglass Cloth is available in a wide range of weights and finishes, allowing for customization to meet the specific requirements of different applications. Whether it is used for aerospace components, automotive parts, marine structures, or construction materials, the company's Prepreg Fiberglass Cloth is designed to deliver outstanding performance in the most demanding environments. With its excellent strength-to-weight ratio and exceptional dimensional stability, this material offers significant advantages over traditional materials such as metal, plastic, or rubber.In the aerospace industry, the company's Prepreg Fiberglass Cloth is widely used in the manufacturing of aircraft components such as fuselage panels, wings, and interior structures. Its high strength and lightweight properties make it an ideal choice for reducing weight and improving fuel efficiency, while also meeting the strict safety and performance standards of the industry. With its superior resistance to extreme temperatures and harsh chemicals, this material is also well-suited for applications in the automotive and marine industries, where it is used in the production of high-performance parts and structures.The construction industry also benefits from the exceptional properties of the company's Prepreg Fiberglass Cloth, which is commonly used in the fabrication of structural components, reinforcing materials, and architectural elements. Its high durability and resistance to corrosion make it an ideal choice for applications in harsh environments such as bridges, buildings, and offshore structures. The material's ease of handling and formability also make it a preferred option for designers and engineers looking to create innovative and sustainable solutions for modern construction projects.Apart from its outstanding physical properties, the company's Prepreg Fiberglass Cloth is also known for its ease of handling and processing. With its compatibility with various manufacturing processes such as molding, compression, and filament winding, this material offers designers and engineers the flexibility to create complex shapes and intricate designs with ease. This not only enables the production of high-performance components but also streamlines the manufacturing process, leading to cost savings and improved efficiency.With its commitment to innovation and technology, the company continues to invest in research and development to further enhance the performance and capabilities of its Prepreg Fiberglass Cloth. Through collaboration with customers and partners, the company seeks to identify new opportunities for applying this advanced material in emerging markets and cutting-edge applications. By leveraging its expertise in advanced materials and its dedication to customer satisfaction, the company is poised to remain a trusted partner for industries seeking high-performance solutions.In conclusion, the company's Prepreg Fiberglass Cloth is a versatile and high-performance material that offers exceptional strength, durability, and versatility for a wide range of applications. With its proven track record of excellence and commitment to innovation, the company is well-positioned to continue its leadership in the field of advanced materials and deliver valuable solutions to its customers across different industries. As the demand for high-performance materials continues to grow, the company's Prepreg Fiberglass Cloth is set to play a key role in shaping the future of advanced manufacturing and engineering.

High-Quality Carbon Aramid Fabric: The Latest Advancement in Textile Technology

Carbon Aramid Fabric, a cutting-edge composite material, is now revolutionizing various industries with its exceptional strength, durability, and resistance to heat and corrosion. This advanced fabric is a combination of carbon fiber and aramid fibers, resulting in a lightweight yet incredibly strong material that can withstand extreme conditions. With its wide range of applications, this fabric is quickly becoming a game-changer in sectors such as aerospace, automotive, marine, and sports equipment manufacturing.The unique properties of Carbon Aramid Fabric make it an ideal choice for industries that require high-performance materials. Its high tensile strength and low weight make it perfect for aerospace applications, where reducing weight while maintaining durability is crucial. Additionally, its resistance to heat and corrosion make it a valuable material for the automotive and marine industries, where components are subjected to intense temperatures and harsh environmental conditions.In the sports equipment manufacturing sector, Carbon Aramid Fabric is being used to create ultra-lightweight and incredibly strong products, such as bicycle frames, tennis rackets, and sports cars. Its ability to enhance performance while reducing weight has made it a sought-after material by athletes and manufacturers alike.One company that has been at the forefront of developing and manufacturing Carbon Aramid Fabric is {}. They have established themselves as a leading provider of advanced composite materials and have been instrumental in bringing this revolutionary fabric to the market. With state-of-the-art manufacturing facilities and a team of skilled engineers and technicians, they have been able to produce Carbon Aramid Fabric at a scale that meets the growing demand from various industries.{} has also been actively involved in research and development efforts to further improve the properties of Carbon Aramid Fabric. By experimenting with different weaving techniques and resin formulations, they have been able to enhance the fabric's mechanical properties, thermal stability, and resistance to environmental degradation. This dedication to innovation has allowed them to stay ahead of the competition and deliver high-quality composite materials to their customers.The company's commitment to sustainability is also evident in their production processes. They have implemented eco-friendly practices in their manufacturing facilities, reducing waste and minimizing their environmental impact. This has made them a preferred partner for companies that are looking to incorporate environmentally friendly materials into their products.In addition to their manufacturing capabilities, {} also provides technical support and consulting services to help their customers integrate Carbon Aramid Fabric into their products effectively. They work closely with design and engineering teams to ensure that the fabric is used to its full potential, resulting in products that are not only strong and durable but also innovative and efficient.As the demand for Carbon Aramid Fabric continues to grow across different industries, {} is well-positioned to meet this demand with their expertise and advanced manufacturing capabilities. They are committed to continuing their research and development efforts to further improve the fabric's properties and expand its applications, cementing their position as a leader in the composite materials industry.In conclusion, Carbon Aramid Fabric is a revolutionary material that is transforming various industries with its exceptional strength, durability, and resistance to heat and corrosion. With companies like {} leading the way in its development and manufacturing, the potential applications for this advanced fabric are endless. As technology continues to advance, the use of Carbon Aramid Fabric is expected to become even more widespread, driving innovation and pushing the boundaries of what is possible in composite material manufacturing.

Carbon Fiber Cloth Sets New Standard for Durability and Strength in Industrial Applications

[Title]: Groundbreaking Woven Carbon Fiber Cloth Revolutionizes the Industry[Subtitle]: Transforming Industries Through Innovation and Excellence[date][City, State] – In a pioneering step towards revolutionizing various industries, an innovative company has introduced a groundbreaking woven carbon fiber cloth that promises to elevate performance and redefine possibilities. With the company name (omitted for anonymity) leading the charge, this cutting-edge technology is set to disrupt existing norms and reshape the future.Woven carbon fiber cloth has long been admired for its exceptional strength-to-weight ratio and versatility. The lightweight yet incredibly strong nature of carbon fibers has allowed various industries to explore new frontiers, from aerospace to automotive, sports equipment, and beyond. However, the latest offering from the undisclosed company takes this utilitarian material to unparalleled heights.Backed by a team of dedicated scientists, researchers, and engineers, the company has harnessed years of expertise to develop an optimized weaving technique that maximizes the potential of carbon fiber. This proprietary process meticulously interlaces the carbon fibers to create a cloth with astounding structural integrity, rigidity, and enhanced functional properties.The woven carbon fiber cloth boasts numerous advantages over traditional carbon fiber materials. Its intricate weave pattern allows for improved load-bearing capacity, ensuring greater durability and longevity. This makes it an ideal choice for applications that require resistance to heavy loads, extreme temperatures, and corrosive environments.Furthermore, this advanced cloth has the unique ability to resist fatigue and withstand repetitive stress cycles without compromising on performance or structural integrity. Industries such as aerospace and automotive manufacturing, where components are subjected to rigorous stress cycles, can greatly benefit from this revolutionary technology.The undisclosed company is particularly excited about the impact their woven carbon fiber cloth will have on the automotive industry. With a relentless pursuit of innovation, they aim to replace conventional materials with this superlative material, leading to lighter and more fuel-efficient vehicles. Reduced weight will not only enhance vehicle performance but also contribute to environmental sustainability by reducing carbon emissions.In addition to automotive applications, this ground-breaking woven carbon fiber cloth holds immense potential in various other sectors. The construction industry can expect sturdier buildings and infrastructure, while sports equipment manufacturers can explore new frontiers in performance-enhancing gear. Moreover, the cloth's corrosion-resistant properties make it an attractive choice for marine applications, offering longevity and structural strength in harsh seawater environments.To ensure widespread adoption of their pioneering technology, the undisclosed company has invested significant resources in research and development and collaborated with industry leaders. Their commitment to excellence and dedication to continuous improvement has cemented their position as a trailblazer in the carbon fiber industry.With the launch of this transformative product, the undisclosed company is poised to drive innovation, reshape industries, and accelerate technological progress. Their unwavering passion for pushing boundaries and their innovative approach promises to shape a future where carbon fiber becomes the epitome of strength, reliability, and sustainability.As the woven carbon fiber cloth continues to gain traction within the market, industry leaders and enthusiasts eagerly await further advancements. The undisclosed company's commitment to excellence, combined with their profound vision for a better future, establishes them as a key player in the carbon fiber industry.About [Company Name]:[Company Name], is an innovative company at the forefront of transforming industries through groundbreaking carbon fiber technology. With a passionate team of experts and cutting-edge research facilities, [Company Name] is redefining the limits of what is possible. Through a commitment to excellence and a relentless drive for innovation, they continue to shape industries and pioneer new solutions that have a lasting impact.

Innovative Fiberglass Cloth: A Solution for Various Applications

Fiberglass cloth has become an essential material in various industries, from construction to automotive manufacturing. Its versatility, durability, and strength have made it a popular choice for reinforcing and insulating materials. One company that has been a leader in the production and distribution of high-quality fiberglass cloth is {}.{} has been a pioneer in the fiberglass industry for over 20 years. The company has established itself as a trusted supplier of fiberglass cloth, offering a wide range of products to meet the needs of customers in different industries. With a strong commitment to quality and innovation, {} has continuously improved its manufacturing processes and product lines to provide customers with the best possible solutions.The fiberglass cloth produced by {} is known for its exceptional strength and durability. It is made from high-quality glass fibers that are woven together to create a tight and uniform structure. This allows the cloth to provide excellent reinforcement for various materials, making it an ideal choice for applications where strength and resilience are crucial.In addition to its strength, fiberglass cloth from {} also offers exceptional thermal and electrical insulation properties. This makes it suitable for use in applications where temperature and electrical conductivity need to be controlled, such as in the manufacturing of electrical components and insulation materials.One of the key advantages of {}'s fiberglass cloth is its versatility. The company offers a wide range of options in terms of thickness, weave pattern, and coating, allowing customers to find the perfect solution for their specific needs. Whether it's for reinforcing composites, insulating surfaces, or providing thermal protection, {} has the right fiberglass cloth for the job.The use of fiberglass cloth from {} extends to various industries, including construction, aerospace, marine, automotive, and many others. Its reliability and performance have made it a go-to material for manufacturers looking to enhance the strength and durability of their products.Furthermore, {} is committed to sustainability and environmental responsibility. The company's fiberglass cloth is produced using eco-friendly processes and materials, ensuring that it meets the highest standards of environmental protection. This not only benefits the planet but also gives customers the peace of mind that they are using a sustainable and responsible material in their products.In conclusion, {} has established itself as a leading supplier of high-quality fiberglass cloth, offering a wide range of solutions to meet the needs of various industries. With its commitment to quality, innovation, and sustainability, {} is well-positioned to continue serving as a reliable partner for manufacturers looking to enhance the performance and durability of their products. Whether it's for reinforcing composites, insulating surfaces, or providing thermal protection, {}'s fiberglass cloth is the perfect choice for those seeking strength, reliability, and sustainability.

Revolutionary Carbon Fiber Camouflage Fabric for Ultimate Stealth

Title: Revolutionary Camouflage Carbon Fiber Fabric Emerges as the Ultimate Stealth SolutionIntroduction: [Company Name], a leading innovator in the textile industry, has recently unveiled its groundbreaking Camouflage Carbon Fiber Fabric – a revolutionary textile that promises to redefine stealth capabilities and revolutionize various industries. This state-of-the-art fabric combines cutting-edge technology and advanced materials, offering unparalleled camouflage properties, durability, and versatility suitable for a wide range of applications.Paragraph 1: Overview and Features of Camouflage Carbon Fiber FabricCamouflage Carbon Fiber Fabric, developed by [Company Name], expands the possibilities for effective camouflage in a diverse array of applications. This groundbreaking fabric is manufactured using a unique blend of advanced carbon fiber and textile technologies, resulting in an ultra-lightweight, exceptionally strong, and flexible material. With its remarkable camouflage capabilities, the fabric enables effective blending into various natural environments, rendering objects virtually invisible to the naked eye.Paragraph 2: Unparalleled Stealth ApplicationsThe introduction of Camouflage Carbon Fiber Fabric opens up new possibilities for a wide range of industries. In the military sector, soldiers and Special Forces can benefit from enhanced camouflage, promoting stealth operations and increasing survivability. The fabric's lightweight and durable nature also makes it ideal for use in protective gear, uniforms, and equipment, further enhancing soldier effectiveness on the battlefield.Paragraph 3: Outdoor Enthusiasts and HuntingCamouflage Carbon Fiber Fabric is poised to revolutionize the outdoor and hunting industry by offering superior concealment to avid adventurers and hunters. This fabric provides enhanced protection against detection by wildlife, ensuring a greater chance of success during expeditions and hunts. Its advanced breathable properties make it comfortable to wear, allowing users to fully immerse themselves into their surroundings.Paragraph 4: Architectural and Interior ApplicationsBeyond military and outdoor applications, Camouflage Carbon Fiber Fabric can also be used in architecture and interior design. The fabric's unique camouflage patterns and ability to blend into various settings open up intriguing design possibilities. It can be utilized to create visually striking art installations, showroom displays, and even versatile room dividers that seamlessly blend into the surroundings.Paragraph 5: Automotive Sector AdvantageIn the automotive industry, Camouflage Carbon Fiber Fabric can be employed to craft high-performance vehicle parts. Its lightweight nature contributes to fuel efficiency, while its extreme durability ensures optimal safety and protection in case of accidents. The fabric's visually appealing camouflage patterns offer automotive enthusiasts an opportunity to personalize their vehicles with a distinct flair.Paragraph 6: Environmental BenefitsCamouflage Carbon Fiber Fabric also offers environmental advantages by promoting sustainability. The material's lightweight, recyclable, and eco-friendly properties make it an attractive choice for companies and individuals striving for a greener future. Its durability ensures a longer lifespan, reducing the need for frequent replacements and minimizing waste.Paragraph 7: ConclusionWith the introduction of Camouflage Carbon Fiber Fabric, [Company Name] has brought forth a game-changing textile that surpasses traditional camouflage materials. Its innovative properties have the potential to transform various industries, from military and outdoor sectors to architecture, interior design, and automotive manufacturing. The fabric's superior stealth capabilities, combined with its lightweight construction and environmental benefits, make it a truly revolutionary solution, revolutionizing the way we approach concealment and aesthetics.

Durable Fiberglass Mat Cloth for Various Applications

Fiberglass Mat Cloth has long been recognized as a versatile and highly effective material used in a wide range of industries including construction, automotive, and aerospace. This highly durable and flexible material is known for its exceptional strength and resistance to heat, chemicals, and corrosion. With a growing demand for high-quality fiberglass mat cloth, [Company Name] has emerged as a leading manufacturer and supplier of this innovative material, offering a wide range of products to meet the diverse needs of its customers.[Company Name] is a renowned company with a strong focus on innovation and quality. With state-of-the-art facilities and advanced technologies, the company has established itself as an industry leader in the production of fiberglass mat cloth. Its commitment to excellence and continuous improvement has positioned [Company Name] as a trusted partner for businesses seeking reliable and high-performance materials for their projects.One of the key features of [Company Name]'s fiberglass mat cloth is its exceptional strength and durability. The material is engineered to withstand the most demanding applications, making it an ideal choice for various industries. Whether it is used for reinforcing concrete structures, manufacturing composite materials, or providing insulation in high-temperature environments, the fiberglass mat cloth from [Company Name] delivers outstanding performance and reliability.Moreover, [Company Name] takes pride in its ability to offer custom solutions to its clients. The company's team of experienced professionals works closely with customers to understand their specific requirements and develop tailored products that meet their unique needs. This level of personalized service sets [Company Name] apart from its competitors and has earned the company a strong reputation for delivering exceptional customer satisfaction.In addition to its commitment to quality and innovation, [Company Name] places a strong emphasis on sustainability and environmental responsibility. The company adheres to the highest standards of environmental stewardship in its manufacturing processes, ensuring that its products have minimal impact on the environment. By utilizing eco-friendly materials and practices, [Company Name] is dedicated to reducing its carbon footprint and promoting a healthier and more sustainable future.As the demand for high-quality fiberglass mat cloth continues to grow, [Company Name] remains at the forefront of the industry, constantly striving to innovate and develop new, advanced products that meet the evolving needs of its customers. With a focus on quality, reliability, and sustainability, [Company Name] is well-positioned to meet the increasing demand for fiberglass mat cloth and maintain its leadership in the market.In conclusion, [Company Name] is a trusted and respected provider of fiberglass mat cloth, offering a comprehensive range of high-performance products tailored to the unique requirements of its customers. With a strong commitment to quality, innovation, and sustainability, the company has established itself as a leading manufacturer and supplier in the industry. As the demand for fiberglass mat cloth continues to rise, [Company Name] is well-equipped to meet the needs of its clients and deliver top-quality solutions for a wide range of applications.

Unidirectional Carbon Fabric: A Breakthrough in Composite Materials

Carbon Unidirectional Fabric is a cutting-edge material that is revolutionizing the way that products are being manufactured across various industries. This innovative fabric, known for its exceptional strength and durability, is being utilized by {Company Name}, a leading company in the manufacturing sector, to create high-quality products that are setting new standards in the market.{Company Name} has established itself as a prominent player in the industry, renowned for its commitment to excellence and innovation. With a strong focus on research and development, the company has been at the forefront of introducing advanced materials and technologies into its manufacturing processes. As part of its ongoing efforts to stay ahead of the competition, {Company Name} has recently incorporated Carbon Unidirectional Fabric into its product line, resulting in a range of superior quality and high-performance offerings.Carbon Unidirectional Fabric is an advanced composite material that is made from carbon fibers that are unidirectionally aligned and then woven together. This unique construction gives the fabric exceptional strength and stiffness, making it ideal for applications that require high mechanical performance. Additionally, the fabric is lightweight and resistant to corrosion, making it a versatile and reliable choice for a wide range of products.By integrating Carbon Unidirectional Fabric into its manufacturing processes, {Company Name} has been able to enhance the performance and durability of its products across various industries. Whether it is in the aerospace, automotive, sports equipment, or marine sectors, {Company Name}'s products are now benefiting from the exceptional properties of this innovative material. With increased strength and reduced weight, the products are proving to be more efficient and reliable, leading to greater customer satisfaction.One of the key factors driving the adoption of Carbon Unidirectional Fabric is its ability to improve the overall performance of products. The fabric's exceptional strength-to-weight ratio allows for the creation of lighter and stronger products, which is particularly beneficial in industries where weight and strength are crucial factors. Furthermore, the superior stiffness of the fabric contributes to better load-bearing capabilities, making it an ideal choice for applications where structural integrity is paramount.In addition to its mechanical properties, Carbon Unidirectional Fabric also offers excellent resistance to environmental factors such as corrosion and fatigue. This makes it a durable and long-lasting material, ensuring that products manufactured with it have a longer lifespan and require less maintenance. As a result, {Company Name}'s products are not only performing better but also lasting longer, leading to increased customer satisfaction and loyalty.{Company Name} has been working closely with its partners and suppliers to ensure seamless integration of Carbon Unidirectional Fabric into its manufacturing processes. By collaborating with experts in the field, the company has been able to leverage the full potential of the material, leading to the development of innovative and high-quality products. This collaborative approach has also helped {Company Name} to stay at the forefront of technological advancements, ensuring that its products continue to meet the evolving needs of its customers.Looking ahead, {Company Name} is committed to further exploring the capabilities of Carbon Unidirectional Fabric and identifying new opportunities for its application. With a strong focus on research and development, the company is continuously striving to push the boundaries of what is possible with this advanced material. By doing so, {Company Name} aims to maintain its position as a leader in the industry and continue delivering exceptional products that set new standards for performance and quality.In conclusion, Carbon Unidirectional Fabric is a game-changing material that is significantly enhancing the performance and durability of products across various industries. When combined with the expertise and innovation of {Company Name}, it is leading to the creation of high-quality and high-performance offerings that are setting new benchmarks in the market. As {Company Name} continues to explore the full potential of this advanced material, it is poised to remain at the forefront of technological advancements and deliver innovative products that exceed customer expectations.

High-Performance Carbon Kevlar Hybrid Fabric: A Breakthrough in Textile Technology

Carbon Kevlar Hybrid Fabric: A Breakthrough in High-Performance MaterialsThe world of materials science and engineering has seen incredible advancements in recent years, leading to the development of innovative materials that push the boundaries of performance and durability. One such material that has been making waves in the industry is Carbon Kevlar Hybrid Fabric. This groundbreaking material combines the strength and lightweight properties of carbon fiber with the impact resistance and toughness of Kevlar, resulting in a fabric that is ideal for a wide range of applications across various industries.The company behind this revolutionary material, {company}, has been at the forefront of materials innovation for over a decade. With a strong focus on research and development, the company has earned a reputation for producing high-quality, cutting-edge materials that meet the demands of modern industries. The Carbon Kevlar Hybrid Fabric is the latest addition to their extensive portfolio of advanced materials, and it promises to set a new standard for high-performance composites.One of the key benefits of Carbon Kevlar Hybrid Fabric is its exceptional strength-to-weight ratio. Carbon fiber is renowned for its high tensile strength and stiffness, making it an ideal choice for applications where weight savings are critical. Kevlar, on the other hand, is known for its superior impact resistance and toughness, making it a popular choice for ballistic protection and other high-stress applications. By combining these two materials into a hybrid fabric, {company} has created a material that offers the best of both worlds – unparalleled strength and durability in a lightweight and flexible form.The potential applications for Carbon Kevlar Hybrid Fabric are vast and diverse. In the automotive industry, the fabric can be used to create lightweight and aerodynamic body panels, improving fuel efficiency and performance. In the aerospace sector, it can be utilized in the construction of aircraft components, where strength and weight are critical factors. In the defense and security industry, the fabric can provide enhanced protection and durability for personnel and equipment. Additionally, it has potential applications in sports equipment, marine technology, and industrial machinery, among others.{Company} has invested heavily in state-of-the-art manufacturing facilities and processes to ensure the highest quality and consistency of their Carbon Kevlar Hybrid Fabric. Their team of expert engineers and materials scientists is constantly pushing the boundaries of what is possible, seeking new ways to improve and customize the material to meet the specific needs of their clients.Another significant advantage of Carbon Kevlar Hybrid Fabric is its versatility. The fabric can be tailored to meet a wide range of performance requirements, from ultra-lightweight and flexible to extremely rigid and impact-resistant. This level of customization makes it an attractive option for companies and industries looking to optimize the performance of their products and components.As environmental concerns continue to grow, the need for sustainable and eco-friendly materials has become a top priority for many companies. {Company} recognizes this need and has developed their Carbon Kevlar Hybrid Fabric with a strong focus on sustainability. The fabric is designed to be recyclable and has a low environmental impact, making it an attractive option for companies looking to reduce their carbon footprint.The future looks bright for Carbon Kevlar Hybrid Fabric, as it continues to gain traction in a wide range of industries. With its unmatched strength, lightweight properties, and versatility, it is poised to become a go-to material for companies looking to push the boundaries of what is possible.In conclusion, {company}'s Carbon Kevlar Hybrid Fabric represents a significant leap forward in the world of high-performance materials. Its unique combination of carbon fiber and Kevlar provides a level of strength, durability, and flexibility that is unmatched by other materials. As industries continue to seek lightweight, strong, and versatile materials, Carbon Kevlar Hybrid Fabric is positioned to become a key player in the global materials market. With its commitment to innovation, quality, and sustainability, {company} is well-positioned to lead the way in the development and commercialization of this groundbreaking material.